Low speed Big Load Roundness Measuring Instruments

Low speed Big Load Roundness Measuring Instruments adopts a self-developed telescopic measuring mechanism, which is convenient and space saving for measurement. The rotary measuring turntable of the instrument adopts a high precision air bearing spindle structure, and the spindle of the instrument has high precision, no wear, and a long service life;The spindle motor adopts imported high-precision AC servo motor and self-developed flexible coupling, making the rotation accuracy of the instrument spindle more stable and reliable.

Features:

Low speed Big Load Roundness Measuring Instruments

* The instrument adopts a self-developed telescopic measuring mechanism, which is convenient and space saving for measurement. The rotary measuring turntable of the instrument adopts a high precision air bearing spindle structure, and the spindle of the instrument has high precision, no wear, and a long service life;

* The spindle motor adopts imported high-precision AC servo motor and self-developed flexible coupling, making the rotation accuracy of the instrument spindle more stable and reliable.

* The instrument adopts the WINDOWS operating platform and professional measurement software, with a simple and intuitive measurement interface and convenient operation; Real time display of graphic data, saving and archiving, printing at any time, graphic analysis reports, intuitive and clear;

*The vertical and horizontal movements of the sensor are controlled by both electronic and manual means, making the equipment easy to operate and precise to adjust;

*It can perform spectral analysis on the surface state of parts and provide the amplitude of any wave; Automatic recognition of interruptions, automatic and manual removal of notches, and measurement of roundness for some arcs;

*Measurement operation settings include mouse and keyboard shortcuts, allowing users to freely choose according to their operating habits.

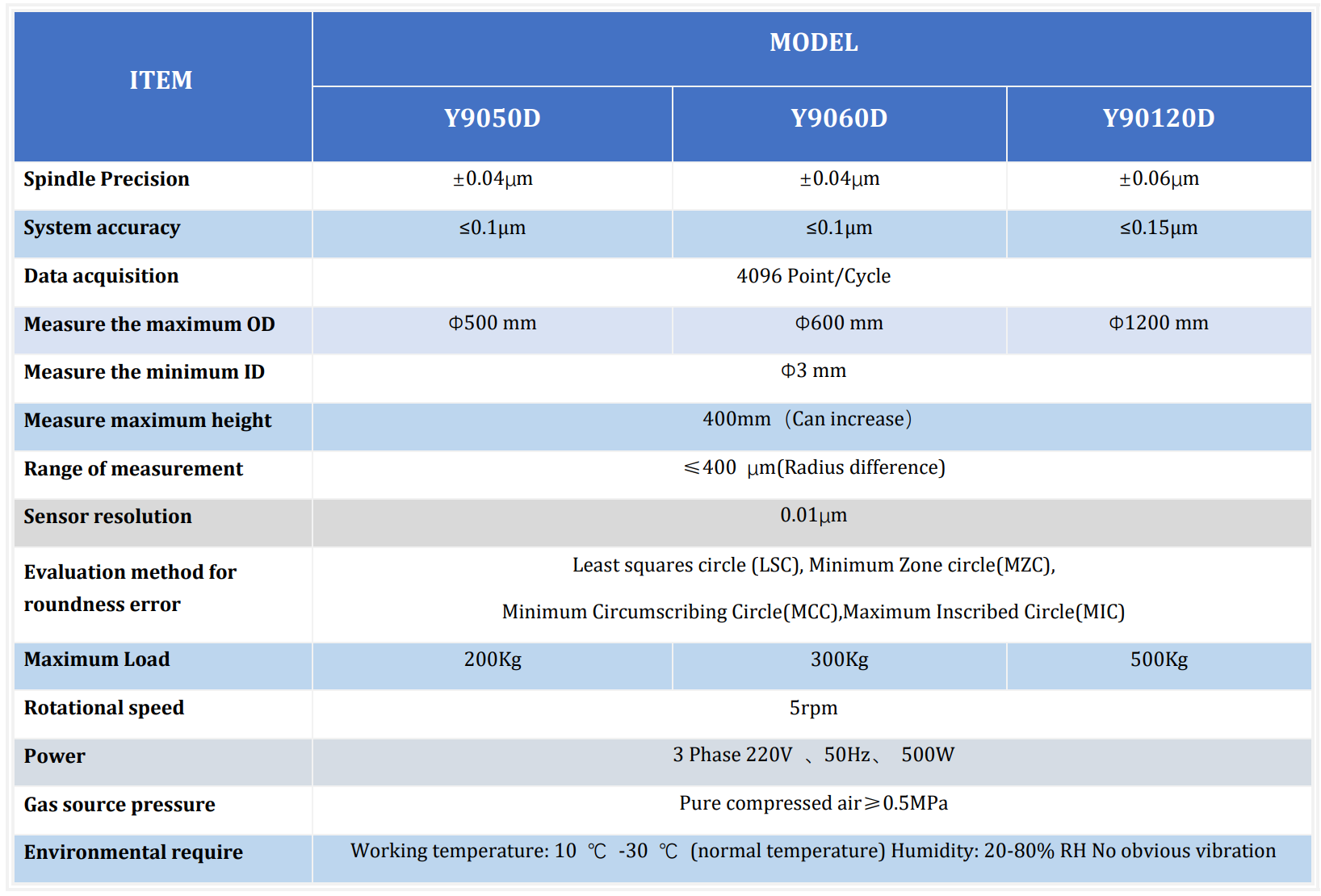

Y90D series Low speed Big Load Roundness Measuring Instruments is suitable for measuring the roundness, waviness and other parameters of large annular workpieces with a diameter less than 1.2 meters and a weight less than 500kg, as well as various large bearing inner and outer ring raceways (roundness error can be evaluated using four methods), and can provide the eccentricity and phase of the parts. It can also be used for measuring parameters such as roundness, runout, single piece runout, and inter piece runout of various motor rectifiers, and can provide the eccentricity and phase of the parts.

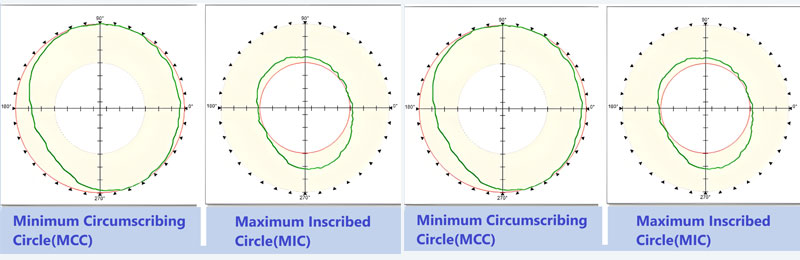

Evaluate method

Least squares circle (LSC),Minimum Zone circle(MZC),

Minimum Circumscribing Circle(MCC),Maximum Inscribed Circle(MIC)

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Jason Pei

Phone: +86-519-89821556

E-mail: instrument@billicomgroup.com

Whatsapp:+86-13584320895

Add: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China