Laser Interferometers

Laser interferometers use light waves as carriers, and their wavelength can be directly defined for meters, which can be traced back to national standards. They are widely recognized as high-precision and high-sensitivity measuring instruments and are widely used in high-end manufacturing fields.

Laser interferometers use light waves as carriers, and their wavelength can be directly defined for meters, which can be traced back to national standards. They are widely recognized as high-precision and high-sensitivity measuring instruments and are widely used in high-end manufacturing fields.

The DFI-6 laser interferometer integrates optical, mechanical, electrical, and computer technologies. The product uses imported high-performance helium neon lasers with a lifespan of up to 50000 hours. It adopts laser dual longitudinal mode thermal stabilization technology, which can achieve high-precision, strong anti-interference ability, and long-term stable laser frequency output. It adopts high-speed interference signal acquisition, conditioning, and subdivision technology, which can achieve a measurement speed of up to 4m/s and nanometer level resolution. The high-precision environmental compensation module can achieve automatic compensation of laser wavelength and material; Adopting high-performance computer control system and software technology, supporting Chinese and English languages, friendly human-machine interface, guided operation process, and simplified record management.

Features:

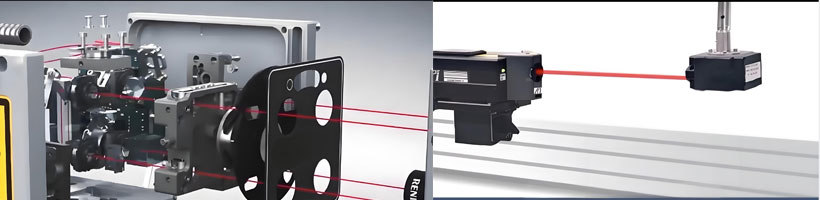

The DFI-6 laser interferometer has the advantages of high measurement accuracy, large measurement range, fast measurement speed, and high resolution at the highest speed measurement. Combined with different optical mirror groups, it can achieve high-precision measurement of geometric parameters such as linear length, angle, straightness, perpendicularity, parallelism, and flatness. With the help of DFI-6 laser interferometer dynamic measurement software, dynamic measurement and performance testing of linear displacement, angle and straightness can be achieved, as well as dynamic analysis of displacement, velocity, acceleration, amplitude and frequency, such as vibration analysis, dynamic characteristic analysis of screw guide rail, response characteristic analysis of drive system, etc.

1. By combining different optical lens groups, high-precision measurements of geometric parameters such as linearity, angle, straightness, perpendicularity, parallelism, flatness, and rotation axis can be achieved;

2. Check the linear positioning accuracy, repetitive positioning accuracy, pitch angle, torsion angle, straightness, verticality, etc. of the guide rails of precision motion equipment such as CNC machine tools and coordinate measuring machines;

3. Implement measurement and calibration of the machine tool's rotary axis;

4. Automatically generate an error compensation table based on the compensation method set by the user, providing a basis for device error correction;

5. It has dynamic measurement and analysis functions, including displacement analysis, velocity analysis, acceleration analysis, amplitude and frequency analysis, etc. It can perform vibration analysis, dynamic characteristic analysis of screw guides, response characteristic analysis of drive systems, etc;

6. Support manual or automatic environmental compensation.

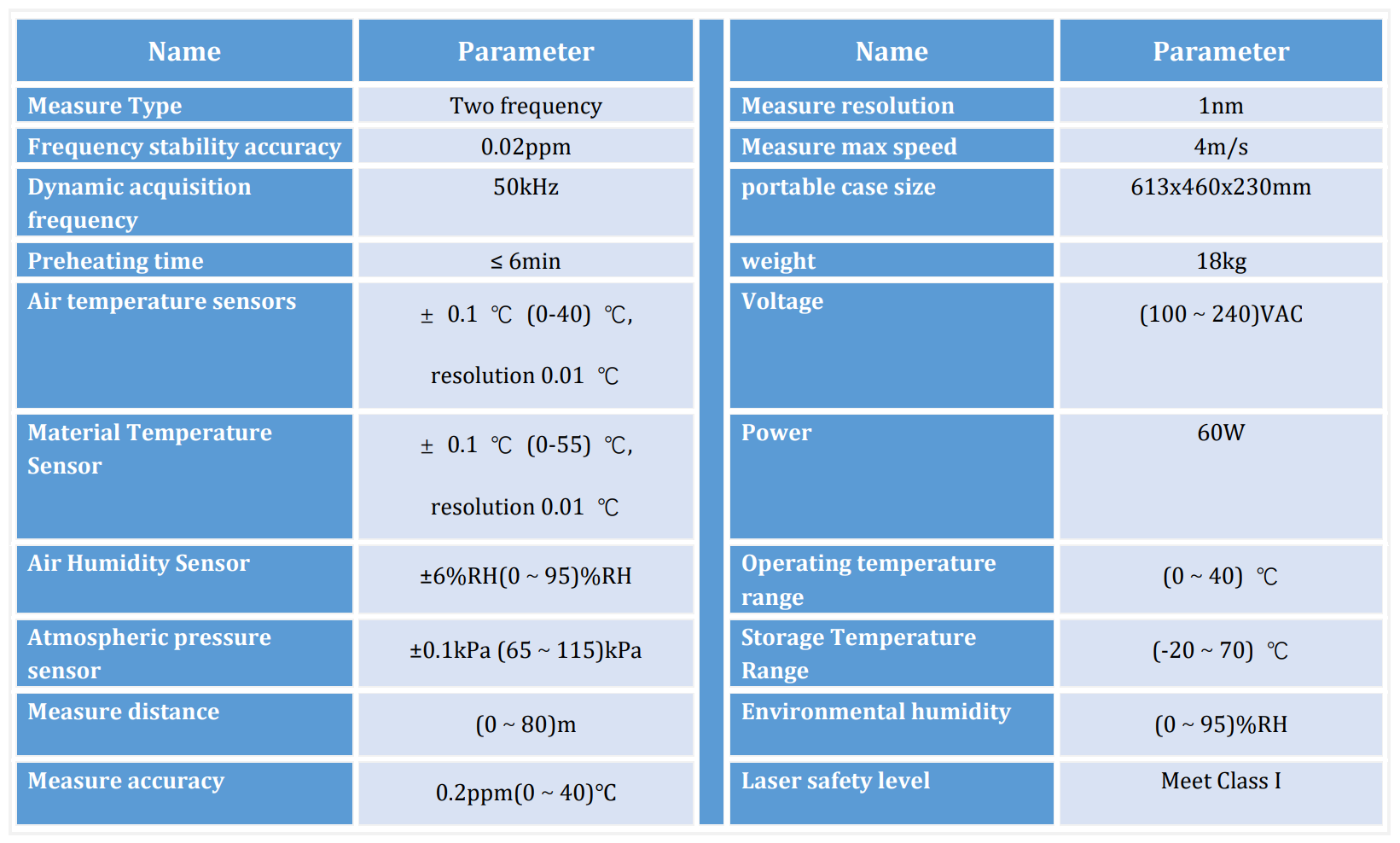

Technical parameter of Laser Interferometers:

Laser interferometer is a high-precision measuring tool that uses the principle of laser interference to measure the size and position changes of objects. It has a wide range of applications in many fields, and the following are some typical scenarios for using laser interferometers:

In the cutting-edge field of modern manufacturing:

Laser interferometers play a crucial role. In precision measurement in industrial manufacturing, laser interferometers can achieve sub micron or even nanometer level displacement measurement, making them an indispensable tool in the development and production of precision instruments.

In mechanical processing and precision manufacturing:

Laser interferometers are used to calibrate the accuracy of machine tools, measuring tools, and machined parts. For example, in integrated circuit manufacturing, laser interferometer is the core component for online displacement measurement of lithography machines, used to measure and calibrate the flatness of wafers and the accuracy of lithography equipment.

Surface morphology measurement:

Laser interferometers can measure the roughness and smoothness of microscopic surfaces, and are widely used in fields such as materials science and nanotechnology. Quality control: By using a laser interferometer, the surface morphology and optical properties of optical components can be detected, effectively controlling the quality and performance of the product.

In the biomedical field, biological tissue measurement:

Laser interferometers can measure parameters such as deformation and variables of biological tissues, providing important data for medical research and diagnosis.

In the field of vibration analysis, mechanical component detection:

Laser interferometers can measure parameters such as vibration frequency and amplitude of mechanical components or vibrating bodies, helping to conduct research and debugging in mechanical engineering.

Used as a length reference in the measurement laboratory:

In the aerospace industry, laser interferometers are used to measure and calibrate the precise dimensions of aircraft components, satellite components, and spacecraft.

In the field of optics:

Laser interferometers are used to test and calibrate the performance of optical systems, such as lenses, mirrors, and optical components.

Automobile manufacturers use laser interferometers to ensure the manufacturing accuracy and assembly quality of automotive components.

Laser interferometers play an irreplaceable role in situations that require precise measurement and calibration due to their high precision and non-contact characteristics.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Jason Pei

Phone: +86-519-89821556

E-mail: instrument@billicomgroup.com

Whatsapp:+86-13584320895

Add: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China