Surface Finish & Contour Measuring Instrument

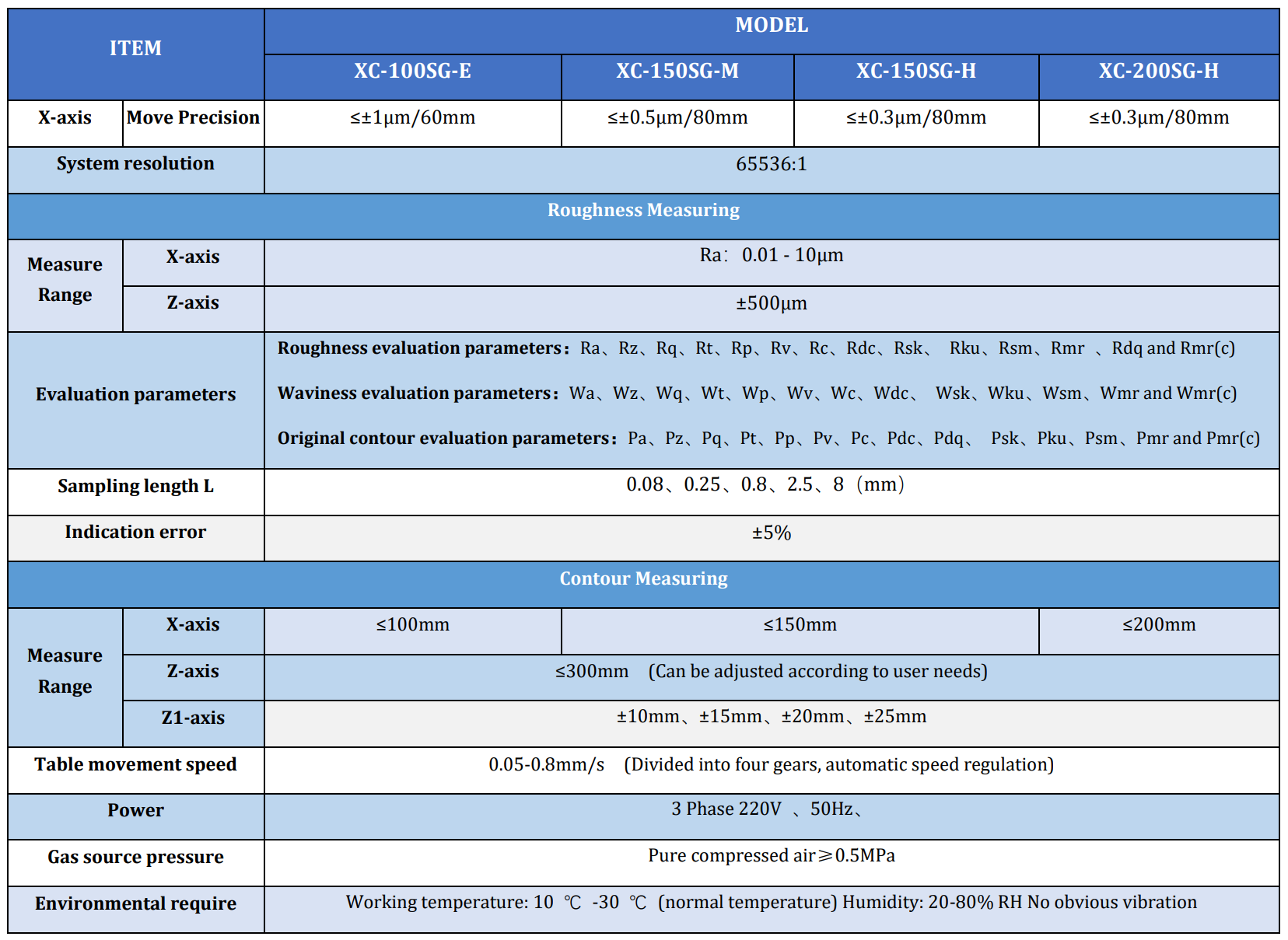

XC series Surface Finish & Contour Measuring Instrument uses the contact method to measure workpieces. The measurement principle is the Cartesian coordinate measurement method, which measures the coordinate points of the surface contour of the measured part through X-axis and Z-axis sensors. And it can evaluate numerous parameters such as surface roughness, waviness, and original contour.

XC series Surface Finish & Contour Measuring Instrument uses the contact method to measure workpieces. The measurement principle is the Cartesian coordinate measurement method, which measures the coordinate points of the surface contour of the measured part through X-axis and Z-axis sensors. And it can evaluate numerous parameters such as surface roughness, waviness, and original contour. The coordinate point data measured by the sensors is transmitted to the upper PC through electrical components, and the software performs mathematical operations on the collected raw coordinate data to annotate the required engineering measurement items.

Main features:

* The instrument Using precision grinding sliding guide as the measurement reference, it has high accuracy and good stability, it never wears out, maintains long-term accuracy, has high linear movement accuracy, and has a long service life for the instrument;

* The displacement data acquisition of linear motion guide rail adopts precision linear grating, with high positioning accuracy and good stability;

*The instrument adopts the WIN11 operating system and is backward compatible with professional measurement software. The measurement interface is simple and intuitive, and the operation is convenient; Real time display of graphic data, saving and archiving, printing at any time, graphic analysis reports, intuitive and clear;

*By using a dedicated control box to communicate with the computer, data transmission is more stable and faster;

*The measurement results can be rotated freely according to the annotation requirements.

*Powerful error compensation function, making measurement results more accurate;

*Measurement operation settings include mouse and keyboard shortcuts, which users can freely choose according to their operating habits;

*Design special assembly fixtures to facilitate the clamping and adjustment of workpieces, greatly improving measurement efficiency;

*Wide range of use and measurement range.

Surface roughness, waviness.

Dimensions: including horizontal distance, vertical distance, linear distance, radius, diameter

Angle:including horizontal angle, vertical angle, and angle

Shape tolerance:including straightness, convexity, and arc

Contour assisted generation: including auxiliary points and auxiliary lines

XC series Surface Finish & Contour Measuring Instrument can measure the elemental and cross-sectional profile parameters of various mechanical parts. Evaluation of surface roughness, waviness, and other parameters. It can measure the straightness, inclination, angle processing, circle processing (distance from line to tangent, distance from center to center, arc radius, distance from intersection point to center of circle, distance from center to line), point line processing (distance from intersection point to line, distance from intersection point to center, intersection of two lines, distance from intersection point to intersection point), logarithmic curve, groove width, groove depth, groove edge distance, groove center distance, inclination, horizontal distance, vertical distance and other shape parameters of various parts. Suitable for industries such as bearings, mechanical processing, automobiles, motorcycles, precision hardware, precision tools, molds, cutting tools, optical components, etc.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Jason Pei

Phone: +86-519-89821556

E-mail: instrument@billicomgroup.com

Whatsapp:+86-13584320895

Add: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China